Welcome!

Dear user, thank you for using the CIRCOPACK tool, which is the result of the CIRCOPACK project. If you have any questions regarding this tool of if you require assistance to use the tool, please feel free to contact info@pack4food.be.

The CIRCOPACK tool

The objective of this online tool is to support companies in making informed decisions regarding sustainable material choices for food packaging. Therefore the whole value chain, including food losses are incorporated in the tool.

The objective of this online tool is to support companies in making informed decisions regarding sustainable material choices for food packaging. Therefore the whole value chain, including food losses are incorporated in the tool.

Users will be able to simulate the environmental impact (resource footprint, global warming potential and total impact score) of a chosen type of primary packaging or a combined food-packaging system.

To do this, input is needed from the user (e.g. type & weight of the packaging material or food) and some assumptions can be made (e.g. food loss). More information regarding these assumptions can be found in the tab “background information”.

The CIRCOPACK tool will allow you to automatically compare multiple simulations, so that any difference in environmental impact becomes visible. This way, an informed decision can be made

The CIRCOPACK project

Project ID Card

| Acronym | CIRCOPACK |

|---|---|

| Title | HBC.2018.0433 - CIRCOPACK: VEILIGE EN PERFORMANTE VOEDSELVERPAKKINGEN BINNEN CIRCULAIRE ECONOMIE |

| Type of project | COOCK |

| Funding | 60 % subsidized by VLAIO |

| Duration | 1st of April 2019 – 30th of June 2022 |

| Number of participating companies | 31 from 3 different countries |

|

Motivation for the project

More scientific knowledge and quantitative data on environmental sustainability are needed to be able to assess the optimal type of food packaging material in relation to the packed food. The shelf life of the food remains crucial when evaluating packaging concepts in order not to create more food losses and hence, increase the environmental foot print. Essential in the project is the incorporation of the whole value chain from raw material to end-of-life.

Innovative character of CIRCOPACK

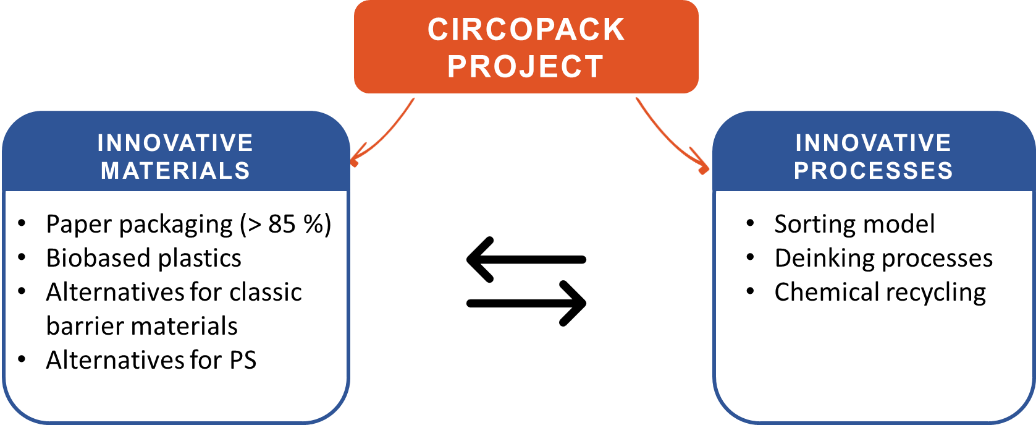

The vision of the CIRCOPACK project was to focus on innovative materials, innovative processes and the interaction between these two sides (see figure 1).

Figure 1. Overview of innovative materials and processes of CIRCOPACK

As a logical consequence, this vision on innovation became visible in the seven different cases of the project (see research approach).

Research approach

CIRCOPACK was a collective research, development and dissemination project (type COOCK) that ran from the 1st of April 2019 until 30th of June 2022.

The project followed a case based approach, which meant that generic case studies needed to be defined. This led to the creation of seven different cases. Five out of these seven cases were related to the following food product with either a short, medium or long shelf life:

- Unpeeled potatoes

- Fresh cut vegetables

- Sliced cheese

- Soy dessert pudding

- Dry biscuits

For each of these food cases, the currently used packaging material was compared to multiple alternative sustainable (recycled / bio-based) alternative packaging materials. This comparison was made possible by the research partners conducted experiments with both the reference and alternative materials. The following aspects were tested during the project

- Sortability

- Mechanical recyclability

- Influence on the shelf life of the food product

- Migration testing

- Odour characterization

- Material properties (e.g. barrier properties, mechanical properties)

The data from the experiments on the current and alternative packaging materials were eventually used as a part of the LCA studies (Life Cycle Analysis) for each of the cases. More information regarding these LCA studies and the assumptions that were made, can be found in the tab “background information”.

Next to the food cases there were also two additional cases which focused on the following recycling aspects:

- Chemical recycling

- Influence of deinking processes on recyclability

Project partners

The project was managed and coordinated by Pack4Food and Flanders' FOOD.

|  |

Furthermore, the following research groups and partners have collaborated to carry out the project:

| Ghent University |

| Sustainable Systems Engineering (STEN) research group from Ghent University |

| Center For Polymer & Material Technologies (CPMT) research group from Ghent University |

| Laboratory for Circular Process Engineering (LCPE) research group from Ghent Universityy |

| The Food Microbiology and Preservation (LFMFP) research group from Ghent University |

| The Food Chemistry and Human Nutrition (NutriFOODchem) research group from Ghent University |

| SENSTECH-SENSNET vzw |

| | UHasselt |

| MPR&S, the packaging technology center at Hasselt University |